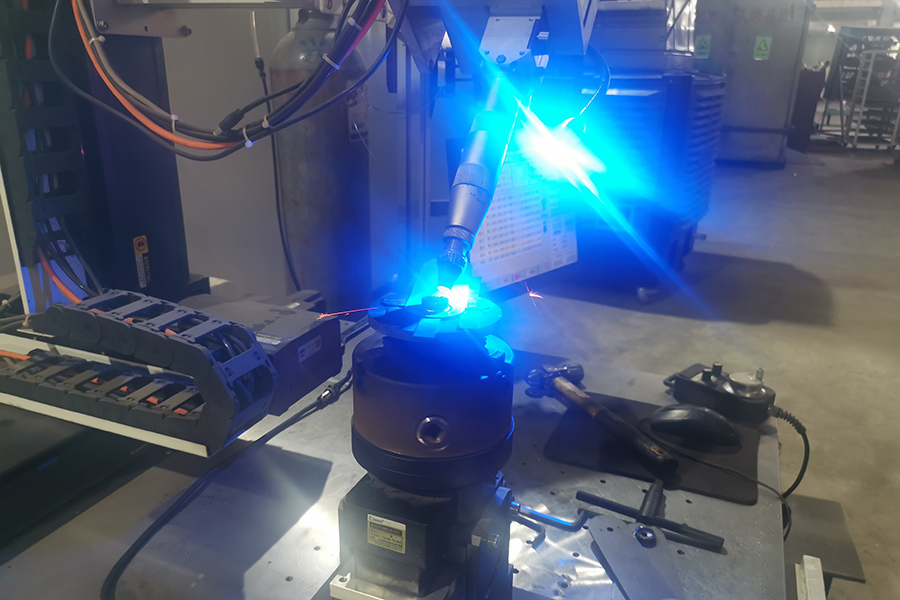

Spot welding in TEVA

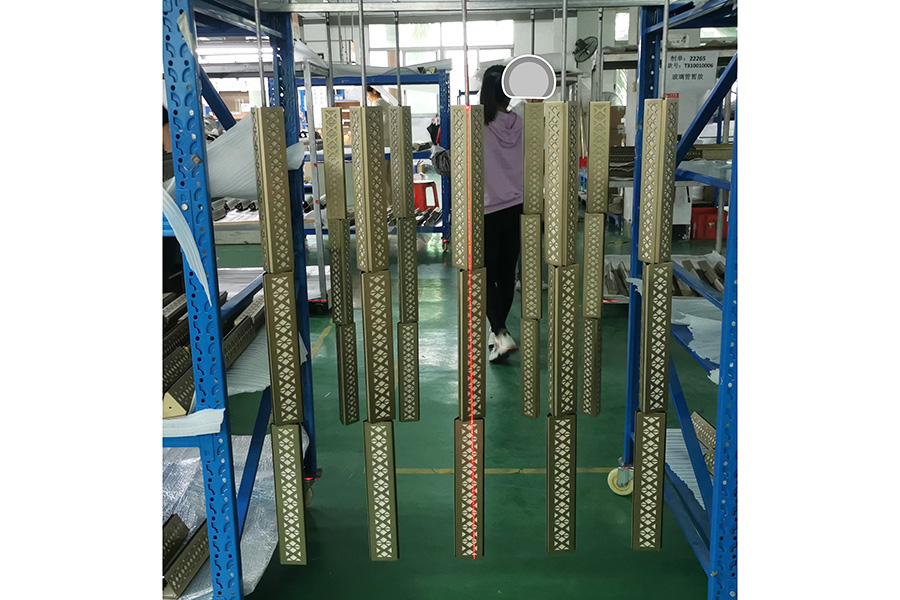

luminaires processing

Spot welding has widely used in the production of customized lighting fixture in TEVA, Easy handling and fast welding time is spot welding’s advantages. It is a reliable, efficient, and affordable method for creating clean, strong welds that can last for decades. However, using spot welding effectively requires careful handling, jigs, and other factors to prevent defects and ensure a high-quality weld.

The Step To Successful Spot Welding

♦ Each of our operators each have at least 10 years of experience in the welding. they work strictly according to the drawings and technical requirements to carry out operations and self-inspection. To ensure the quality of our products

In conclusion, our customized lighting fixture brought to you through innovative and state-of-the-art spot welding techniques is the perfect lighting solution for any space. With its durability, safety, versatility, and energy efficiency, you can be assured that it is not just an excellent purchase, but an investment that will last for many years.