Polishing in TEVA’s

luminaires processing

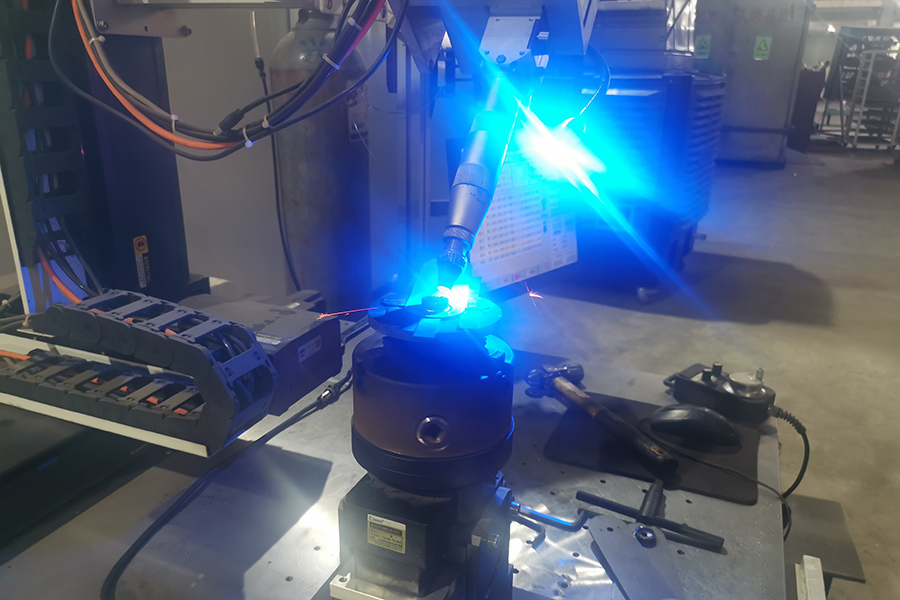

Polishing is a necessary process before surface treatment, usually required before and after welding. It is about the success of the surface treatment.

Grinding and polishing processes ensure that the surface of the metal is smooth and free from any defects.

Polishing are important because they remove any impurities from the metal surface , which can cause defects in the surface treatment.

Unleash Brilliance with TEVA's Polishing in Luminaires Processing - Elevate Your Illumination Experience!

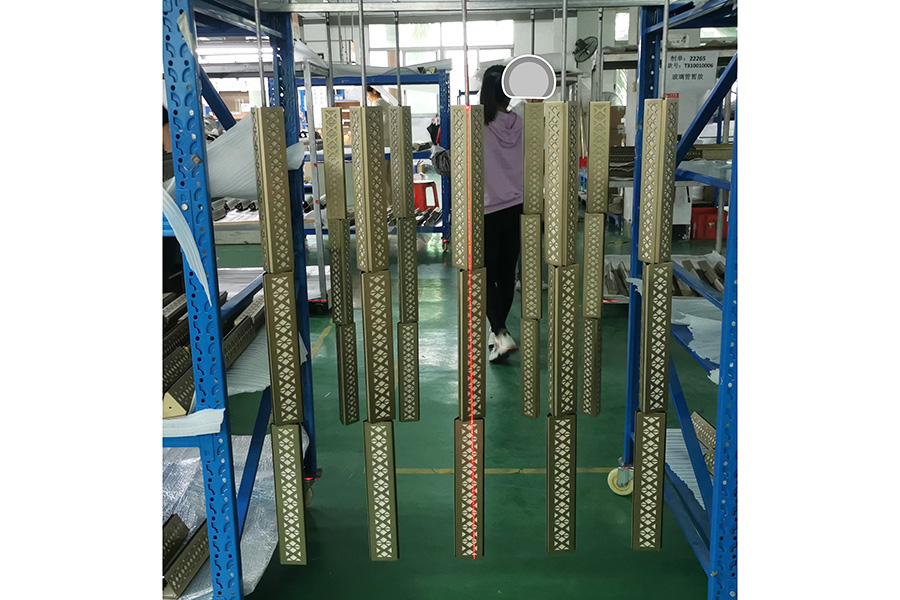

Step into a world of radiant elegance with TEVA's Polishing in Luminaires Processing. Our meticulous craftsmanship and cutting-edge polishing techniques breathe life into each luminaire, transforming ordinary lighting into a captivating visual masterpiece.

Experience the allure of perfectly polished surfaces, reflecting light in mesmerizing patterns that enhance any space. From sleek pendant lights to sophisticated chandeliers, our luminaires exude luxury and sophistication.

TEVA's Polishing in Luminaires Processing goes beyond aesthetics, ensuring the utmost precision in every detail. Enjoy the assurance of durable, top-quality lighting fixtures that withstand the test of time.

Illuminate your world with brilliance - embrace the artistry of TEVA's Polishing in Luminaires Processing and elevate your illumination experience to a whole new level. Discover the transformative power of light, reimagined by TEVA.

♦ Mirror polishing, hairline polishing, Vibration polishing can get.

In conclusion, polishing are critical processes that are carried out before surface treatment.