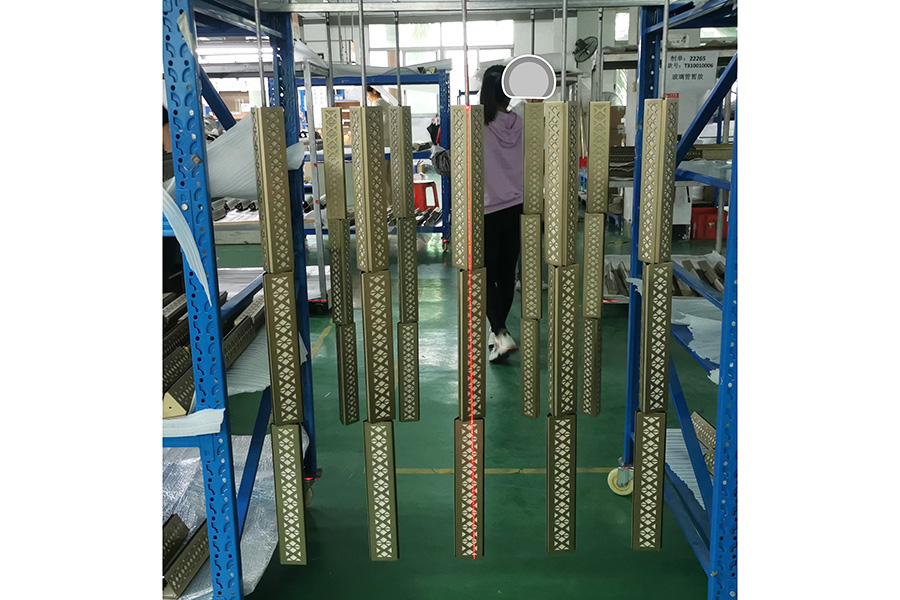

Painting in TEVA’s

luminaires processing

Painting of small and medium-sized parts can be handled in Teva’s factory.

Painting is to stick to a well-defined process that ensures uniformity of the paint coating. This process typically involves cleaning the surface to remove any dust, dirt, or grease that might interfere with the adhesion of the paint. After cleaning, the parts are prepped and primed to provide a smooth layer for the paint to adhere to.

The actual painting comes next, and it is crucial to have the right equipment and skilled personnel to carry out this task expertly. A variety of painting techniques may be used, including spraying, dipping, or brushing, depending on the size and shape of the parts being painted.

The quality of the paint used for painting is also a critical factor. Environmentally friendly paints are preferred, as these are non-toxic and safe for both the workers and the environment. Additionally, the type of paint used must be able to withstand the environmental conditions under which the parts will be used.

Experience Brilliance with TEVA's Luminaires Processing - Unleash the Radiance!

Illuminate your world with the captivating brilliance of TEVA's Luminaires Processing. Our cutting-edge technology and precision craftsmanship come together to create lighting solutions that redefine brilliance and sophistication.

From contemporary designs that enhance modern spaces to timeless classics that exude elegance, our luminaires are meticulously polished to perfection. Each piece is a masterpiece, seamlessly blending aesthetics with functionality.

TEVA's Luminaires Processing is your gateway to a world of enchanting illumination. Whether it's creating an inviting ambiance at home or adding a touch of allure to commercial spaces, our luminaires deliver exceptional performance and energy efficiency.

Unleash the radiance in every corner with TEVA's Luminaires Processing. Elevate your lighting experience and embrace a world illuminated by the finest craftsmanship and innovation. Illuminate your life with TEVA's brilliance today!