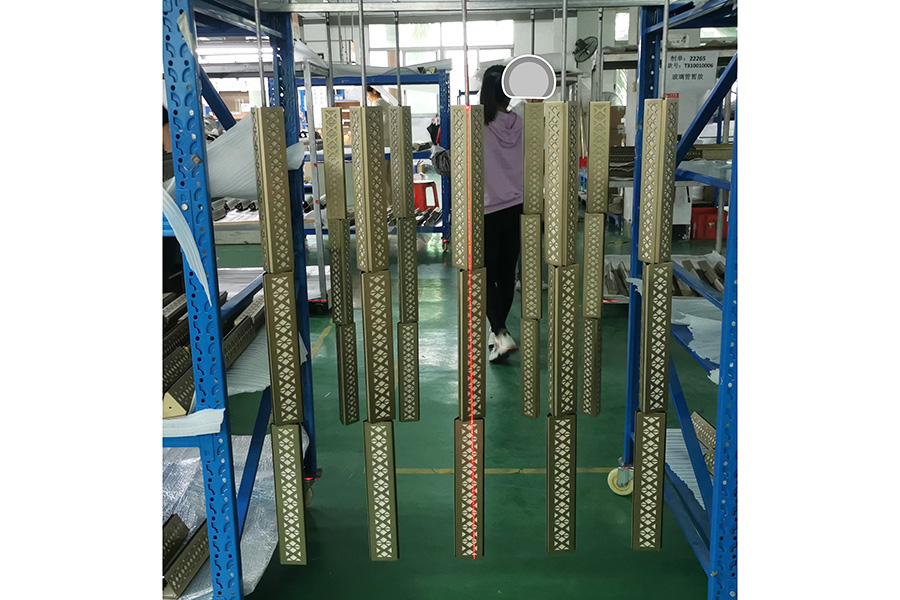

Copper sandblasting

Why is sandblasting used on customized lighting fixture?

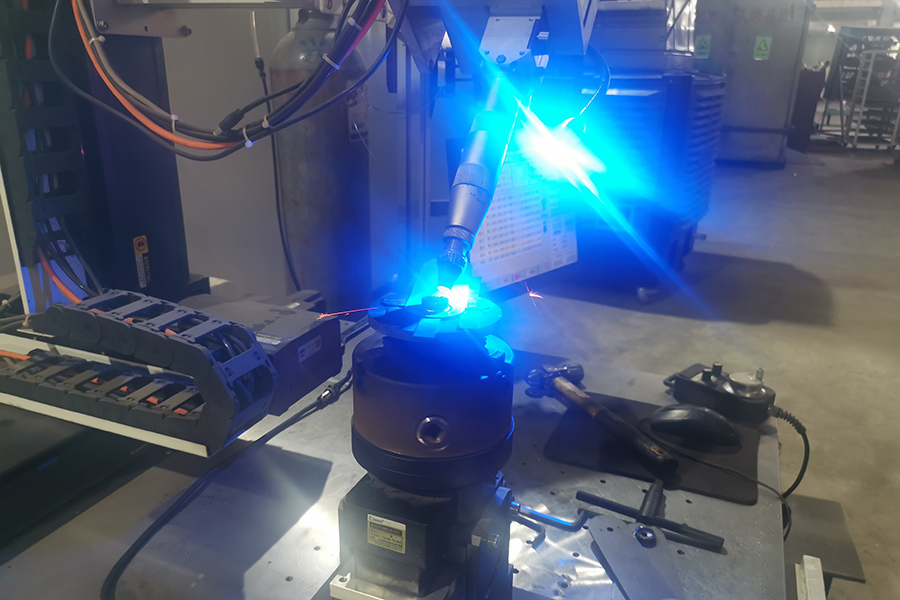

In customized products, there are many parts that need to fully reflect the design highlights. Often, these parts are difficult to process using ordinary mechanical methods. In order to reduce costs , sandblasting is used to realize the designer’s ideas.

One of the main benefits of using sandblasting in the production of lighting fixtures is the impeccable finish it provides. Sandblasting uses a high-pressure abrasive stream to create a smooth, uniform surface texture. This technology helps achieve a stunningly uniform surface that enhances the aesthetics of the lighting fixture. When it comes to lighting fixtures, the uniformity of the finish is crucial, as it ensures an even distribution of light, creating the ideal ambience for any environment.

In addition, sandblasting has other advantages in the customization process. It allows for the creation of unique patterns, textures and designs in various parts of the lighting fixture. The controlled abrasive stream can be precisely directed to remove specific portions of the surface, resulting in unique and eye-catching designs. This level of customization is difficult to achieve using traditional mechanical methods.

Copper is a malleable and malleable metal that is often used in the production of sandblasted lighting fixtures. Copper is a good choice because it is easy to machine and provides a smooth surface texture after sandblasting. Additionally, copper does not rust easily, making it a durable and attractive material for lighting fixtures. The combination of ease of machining and resistance to rust makes copper an ideal material for sandblasted lighting fixtures.